Product Description

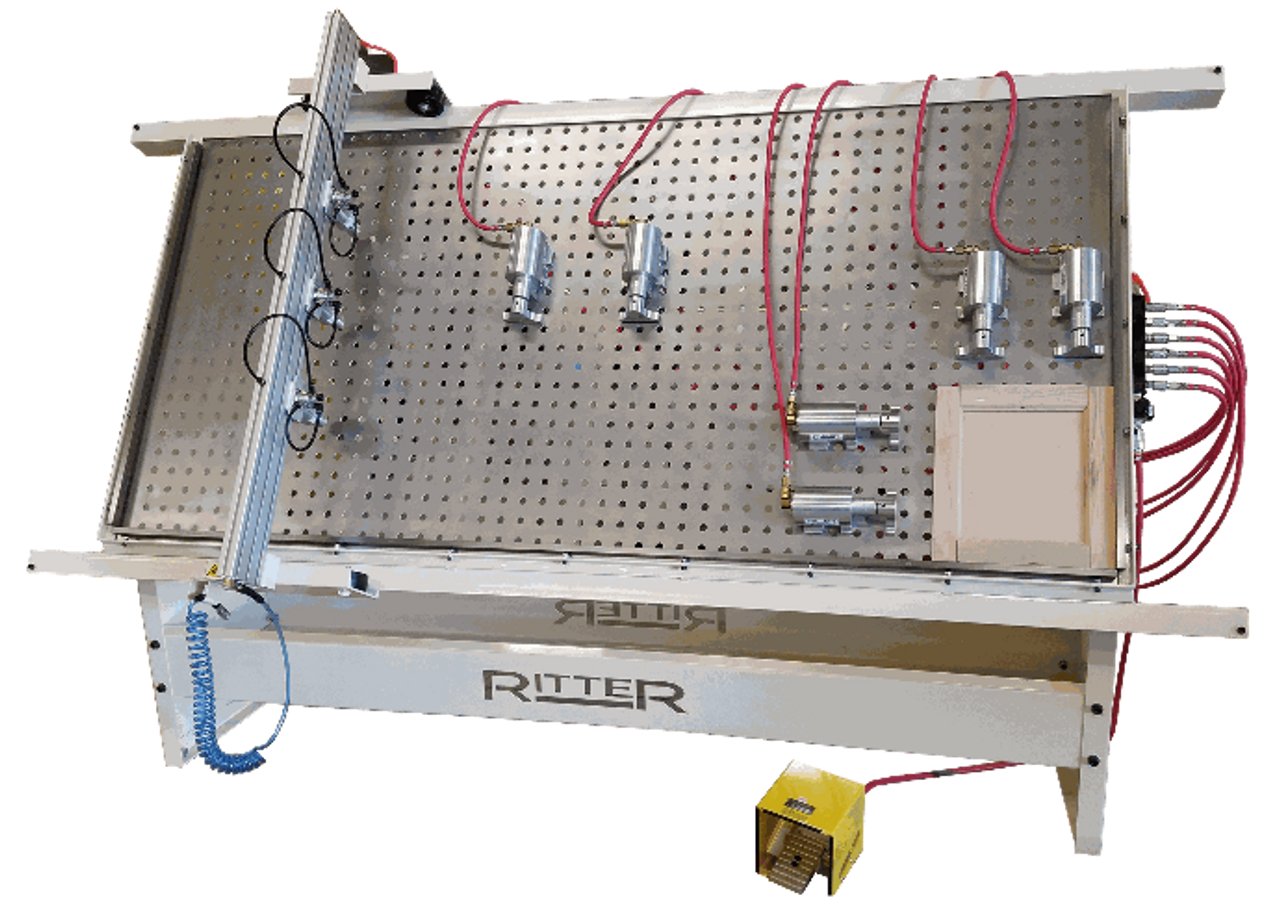

Description:

Frame assembly system for doweled, mortise and tenon, or screwed together frames and cabinet doors. Screwed together face frame construction provides for the most efficient and economical methods for joining frames. Flush and tight joint construction is provided for all types of wood. Elimination of dowel boring and insertion, clamping time and joint misalignment provide up 50% time reduction in frame production. The ability to disassemble and reposition a joint creates less loss of material in case of errors in the joint location. No glue required.

Standard Features:

- 4'x8' Assembly Table

- 30° Vertical Easel

- Hold Down Beam with (3) Adjustable Hold Down Cylinders

- 1-5/16" Clearance Under Vertical Cylinders

- Squaring Bars on Left, Right and Bottom Sides

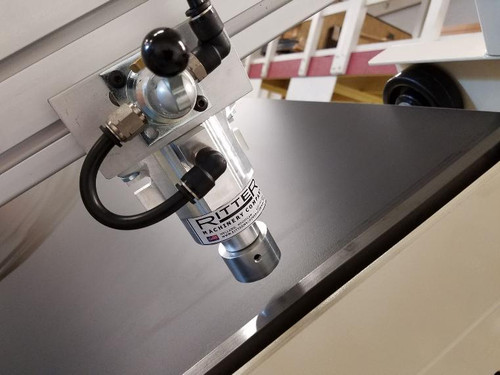

- (4) Universal Clamping Cylinders & Manifold

-

- 706.8 LBS of force at 100 PSI

- 2" Cylinder Position Grid Pattern

- 3" Bore Clamp Cylinder Housing

- Heavy Duty Steel Frame

- Perforated Steel Table

- 6 port Manifold with 1/4" NPT Regulator/Gage

- Adjustable pressure from 20 to 130 PSI

- Foot Treadle

- Heavy Duty Steel Frame

- (1) Coilhose for Pneumatic Screw Gun

- Screw Gun Not Included

Technical Data and Specifications:

- Usable Table Area: 95" x 45.5"

- Work Height: 31"

- Footprint: 115" L x 41" D x 79" H

- Electrical: N/A

- Air: 100 PSI

Additional options:

- R275A - Face Frame Assembly Clamp Arm

- U300E05 - Additional AC-20 Universal Clamp Cylinder

- U37515 - Additional Manifold Assembly

- U300E16 - Additional Foot Treadle Assembly

Shipping Weight: 1000 LBS

Shipping Dimensions: 56" X 120" X 30" H

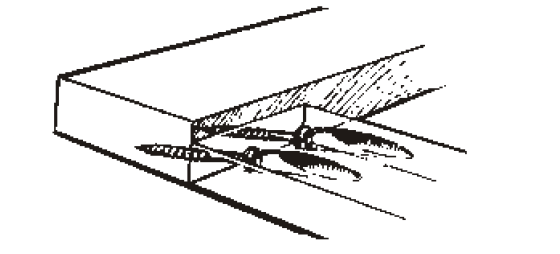

Joint Construction

Material thickness variations do not create misalignment at the face side. This is provided by clamping the material down with the R200A clamp beam. Tight joint construction is provided by the screws being used as the tightening force, not side clamping pressure. The screw angle is adjustable to allow for 5/8” or thicker material.