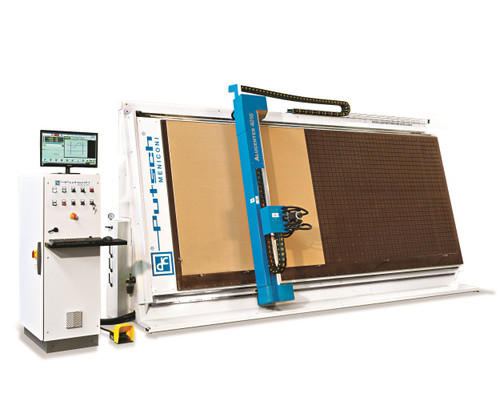

Product Description

The Putsch® Alucenter 4016 Vertical CNC Center offers fabricators a space-saving solution to cut and groove aluminum composite materials (ACM) and high pressure laminates (HPL) like Trespa. The frame is built using a monolithic steel design for strength and rigidity. This robust CNC work center offers precise X, Y and Z axis milling and shaping. The grooved work surface has five vacuum zones that can be selected according to the size and shape of the panel being processed. The operator control is easy to program with macro parametric, CAD-CAM and nesting software integration. Provided with the machine are light barriers that help prevent access to the work area during active machining operations.

- Grooved working table 4000 x 1600 mm with 5 user-selected vacuum zones (MDF panel not included)

- One vacuum pump - 58.86ft3/min (CFM)

- Two electric spindles with ER 25 collets (3 hp – 18.000 rpm)

- Manual tools preset

- Manual rack lubrication for X and Y Axis

- Manual linear guides lubrication

- Two 4 inch (100 mm) dust vacuum openings

- V 400/3/50Hz (transformer recommended for 480V installation)

- Safety zone light barriers with photoelectric cells

- Electric box, wiring and safety protections according to “CE” norms

Control Panel

- Operator workstation with 22’ LCD color screen

- Elcon CAD-CAM programming software including parametric macros and DXF for ACM processing

- One Ethernet port

- One USB port

| X Axis | Y Axis | Z Axis | Max Axis Speed | Overall Footprint | Machine Weight |

| 13' 1" (4000 mm) | 5' 3" (1600 mm) | 2" (50 mm) | 45 - 20 - 10m/min | 17' 6" x 7' x 8' 5" | 5070 lbs |