Product Description

Powerful, precise, and efficient roll feed ripsaws.

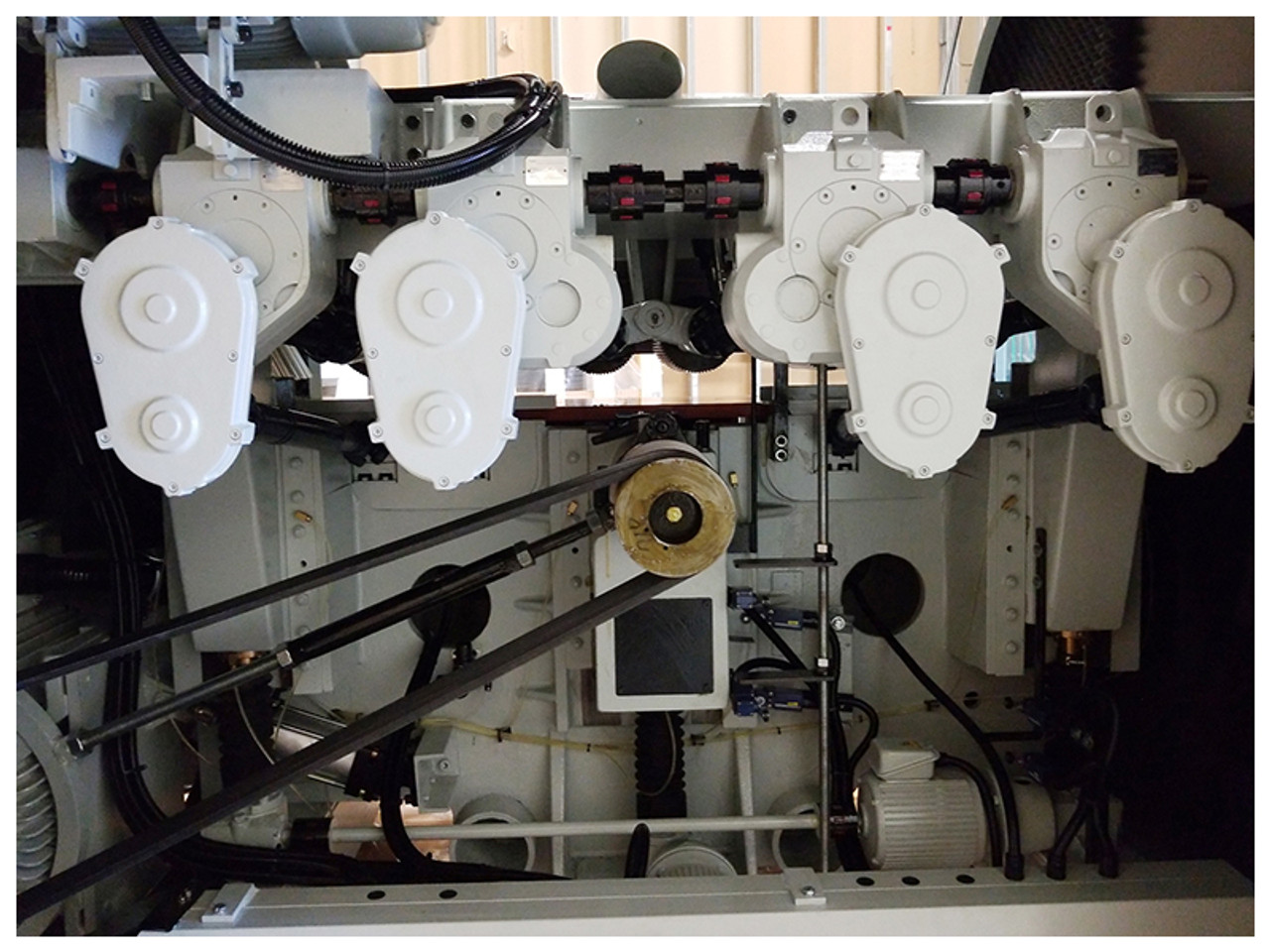

The Leadermac SYC Series Roll Feed Ripsaws has been designed to ensure uncompromised results specifically aimed to the company looking to run strip materials like lath, dunnage, stakes, and more. The roll feed design will rip for maximum material yield which helps increase output and margins.

Why Leadermac SYC Series Roll Feed Ripsaws?

- Roll feed design achieves maximum yield from the material

- Heavy frame ensures smooth running to allow thin cutting of materials like lath

- Full width top and bottom driven feed rolls assist in smooth feeding of a range of materials thru the ripsaw

- Fully enclosed design, along with multiple anti kickbacks ensure a safe operating machine

- Bottom cutting with known safety advantages

- Outboard spindle bearing support for precision cutting results

- Available in a wide range of widths and configurations to suit any applications and budget

- Heavy cast iron base provides best rigidity and reduces vibration for rip cutting results

- (6) top driven feed roll assemblies for optimum material control

- (4) bottom driven feed roll assemblies facilitate in feeding difficult to feed material

- Blades are mounted to a removable saw sleeve which allows the operator to pre-build different ripping setups and facilitates in fast changeovers

- A number of features are integrated in to the machine to ensure safe operation

Working widths |

12”, 16” & 18” (300, 405, & 455mm) options |

Working thickness |

5.1” |

Saws |

10” to 16” Diameter |

Spindle RPM |

4000 RPM (VFD control optional) |

Spindle diameter |

50 mm |

Saw sleeve diameter |

70mm OD with two keyways |

Standard feed speed |

20 to 100 FPM (optional to 200 or 300 FPM) |

Minimum part length |

10″ at slower speeds |

Main Motor |

50, 75, 100, 150 HP options |

Feed motor |

5, 7.5, 10, 15, or 20 HP |