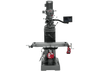

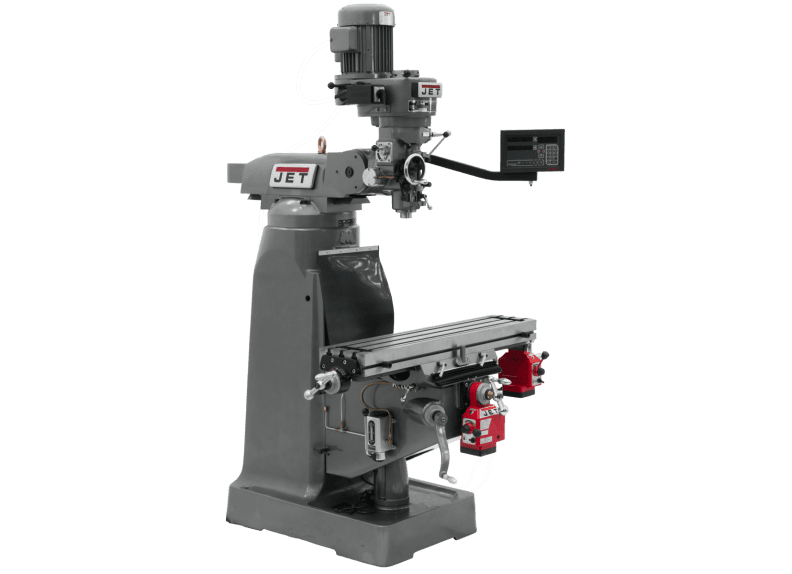

Product Description

The JTM-1 Mill With Newall DP700 DRO With X and Y-Axis Powerfeeds has a three-stage power down feed with automatic stop, high precision Class 7 spindle bearings and the rugged stability of Certified Meehanite® castings ensures you get everything you need from the JTM-1 and 2 models. The internally cooled spindle head prevents seizing, and JET precision engineering ensures superior results with all the features you've come to expect, all backed by the industry-leading JET Two Year Warranty.

| Stock Number | 691189 |

|---|---|

| Collet Capacity | 1/8 - 7/8 |

| Distance Spindle to Column (Max.) (In.) | 19 |

| Max Distance Spindle to Table (In.) | 17-1/2 |

| Motor (HP) | 2 HP, 230V, 3Ph |

| Number of Axis | 2 |

| Number of Spindle Speeds | 16 |

| Overall Dimensions (L x W x H) (In.) | 57 x 64 x 82 |

| Powerfeed | X and Y-Axis |

| Prop 65 | Cancer and Reproductive Harm |

| Quill Diameter (In.) | 3-3/8 |

| Quill Down Feed Rates (IPR) | .0015 - .003 - .006 |

| Range of Spindle Speeds (RPM) | 80 - 5,440 |

| Spindle Taper (In. x TPI) | R-8 |

| Spindle Travel (In.) | 5 |

| Style (Type) | Step Pulley R8 |

| T-Slot Centers (In.) | 2-1/2 |

| Table Cross Travel (In.) | 12-1/2 |

| Table Longitudinal Travel (In.) | 23-7/8 |

| Table Longitudinal Travel With Powerfeed (In.) | 20-2/7 |

| Table Size (L x W) (In.) | 9 x 42 |

| Travel of Knee (In.) | 14-1/2 |

| Travel of Ram (In.) | 13-3/8 |

| Weight (Lbs.) | 2200 |

| Work Table Weight Capacity (Lbs.) | 550 |