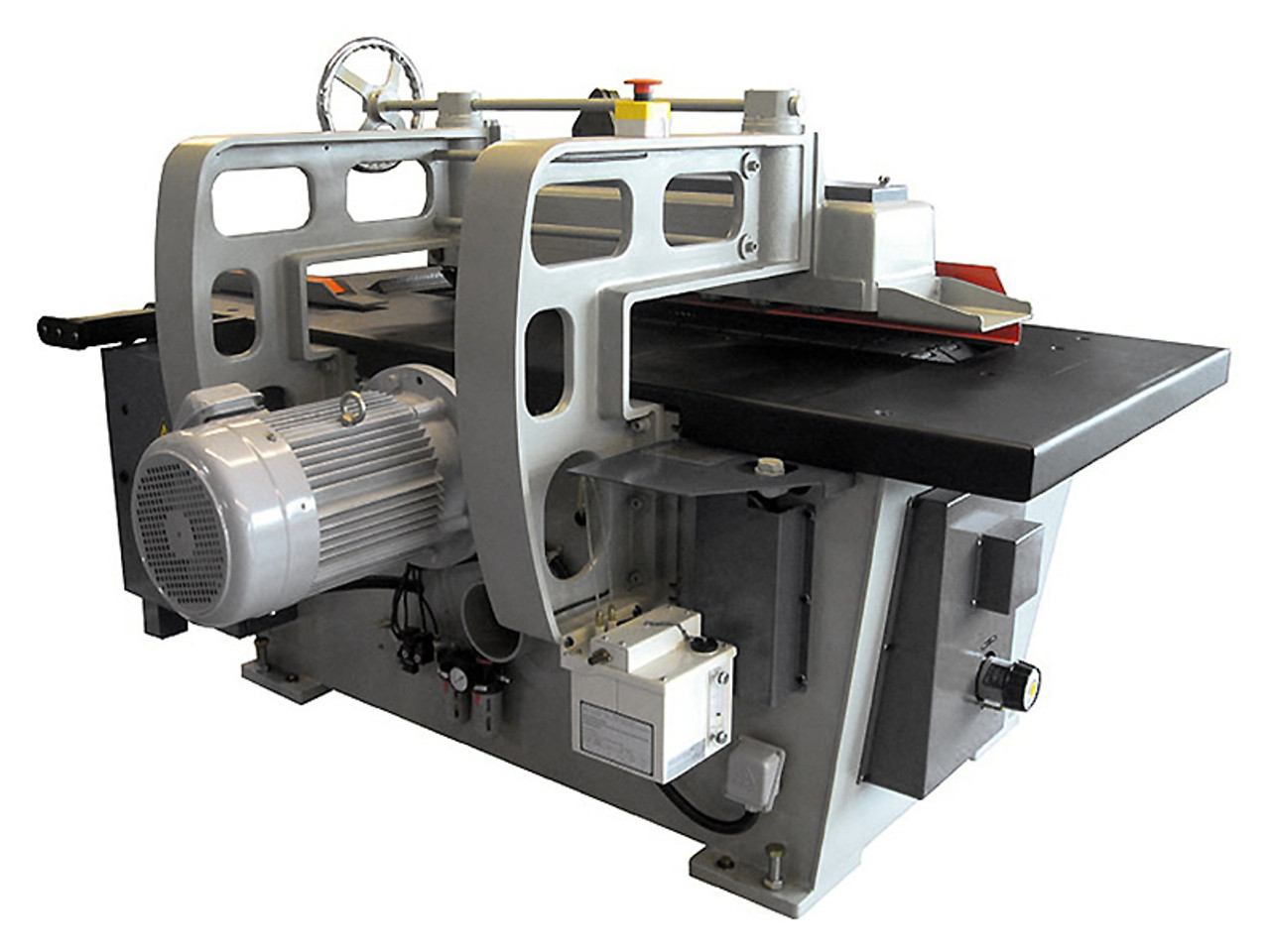

Product Description

A precision straight line ripsaw for high production with improved safety features.

The Cantek R16 bottom cutting straight line ripsaw is designed with performance and added safety in mind. Cutting from below forces the workpiece down on to the feed chain for superior hold down. In addition, the blade can project up above the workpiece to allow the gullet to clear the chips which leads to less heat buildup resulting in longer blade life and improved cut quality. The R16 is capable of producing a glue joint cut up to 8 feet. The powerful 15HP direct drive ensures optimum feed rates no matter what material or thickness you are cutting.

Why Cantek R16 Bottom Cutting Straight Line Ripsaw?

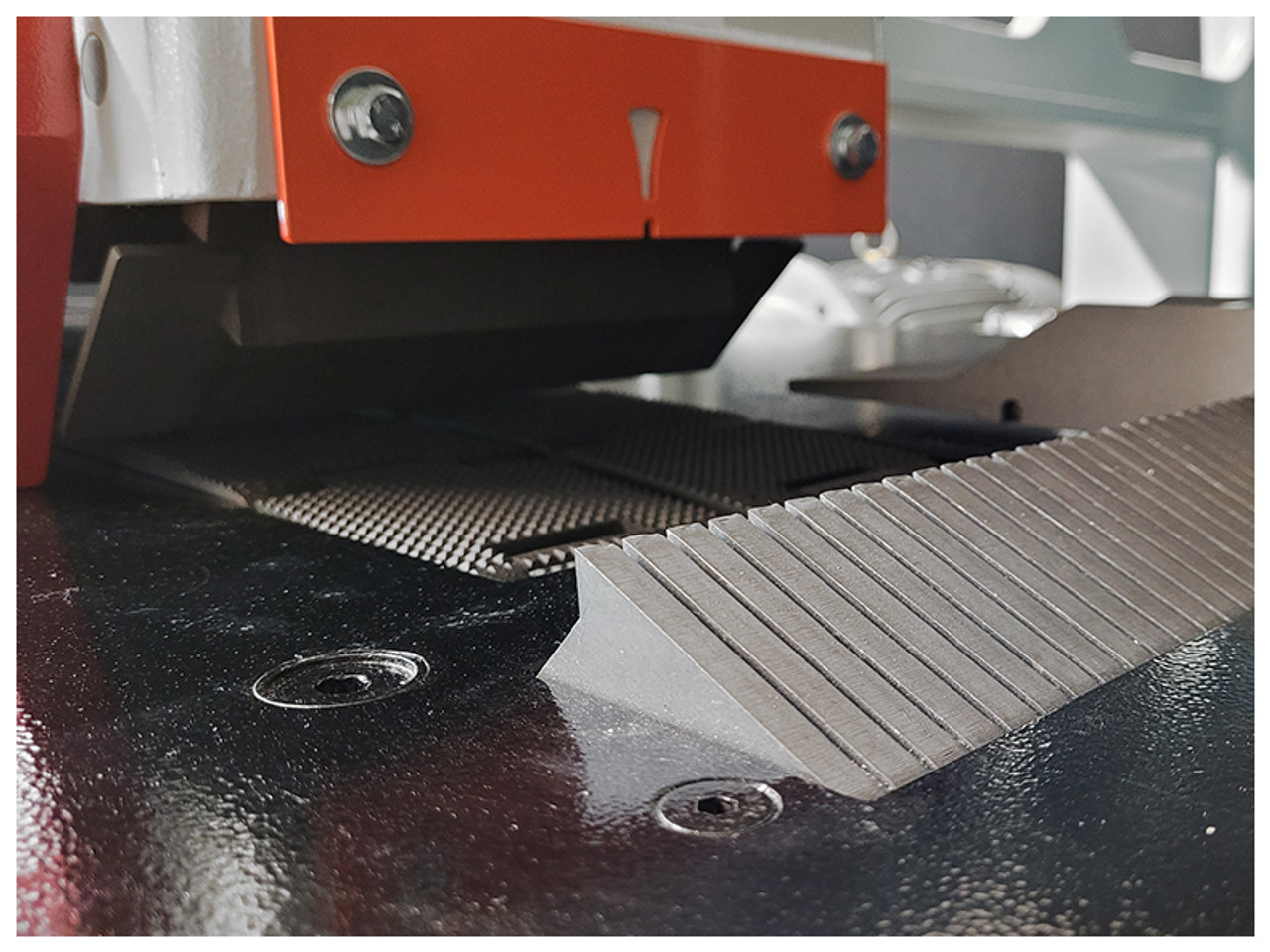

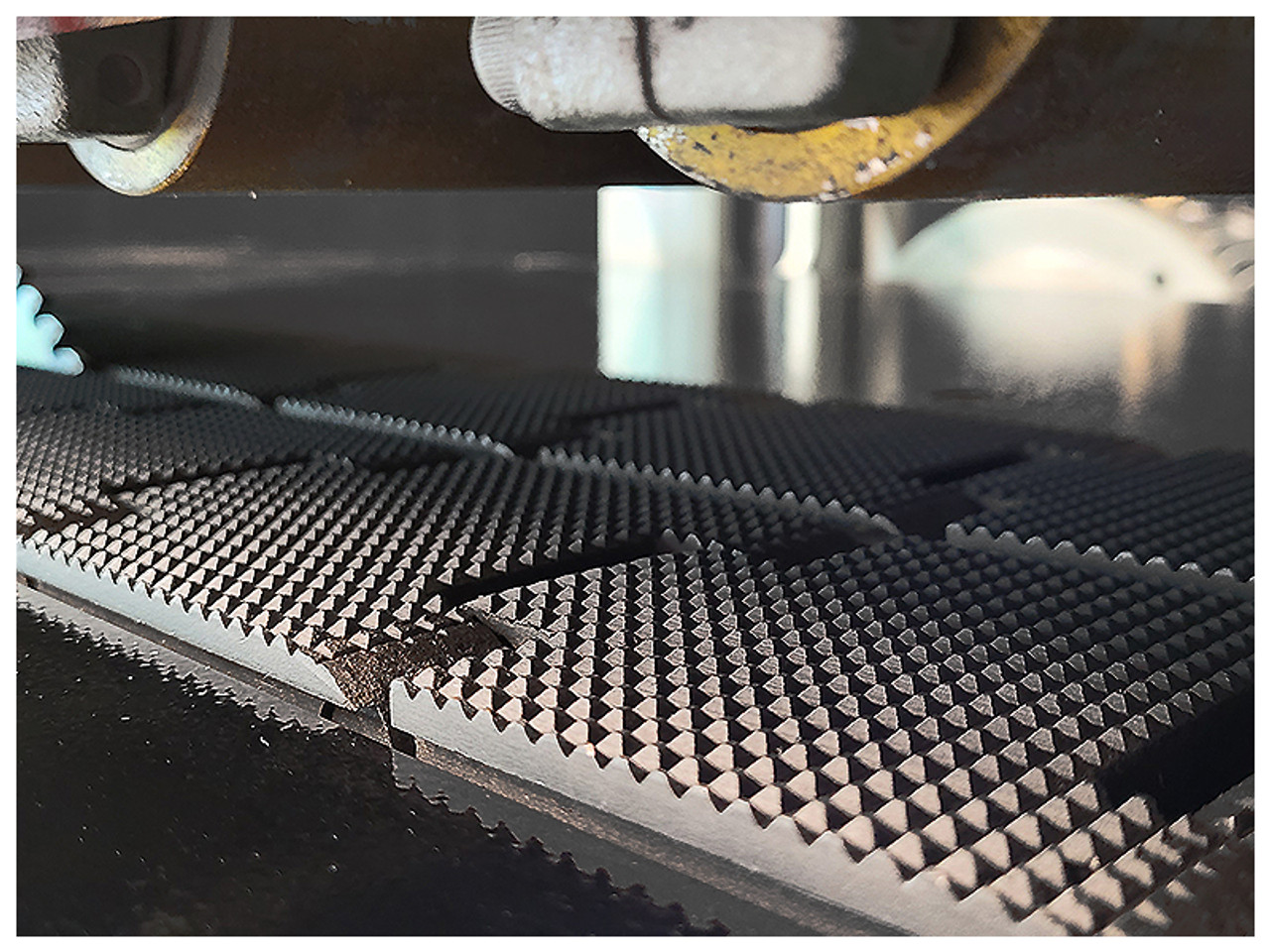

- Cutting from below has a distinct advantage in that the gullet of the sawblade projects above the stock to clear the shavings halfway through the cut providing for superior finish results and extended blade life

- Bottom cutting also forces the material down on to the chain surface providing for safer operation

- Powerful 15HP motor allows for optimum feed speeds no matter what the material or thickness

- Extended hold down assembly with guaranteed glue joint ripping from 1’ to 8’

- Precision cast-iron split feed chain with automatic lubrication for maximum wear protection

- Auto-lowering bottom anti-kickback finders to facilitate with lining up the workpiece on the table

- Extra heavy-duty machine frame made of thick welded steel and cast iron

- Split chain, double feed track with HRC60 Rockwell Hardened Guideways

- Massive steel table with 18” maximum distance to the right of the blade

- (8) hold down rolls and 35” long chain above the table ensures precision straight-line ripping

- Automatic chain and track lubrication system ensures long life of the chain & track assembly

- Saw arbor height is adjusted manually

- Manual rip fence adjustment by handwheel and rack & pinion with dual inch/metric scale

- Manual thickness adjustment with linear scale

- Saw arbor brake included

- Anti-kickback fingers top and bottom for safe operation

- Safety interlock on access door

- Comes with 14” rip saw blade: 14mm pin holes on 65mm centers

- Optional laser light to project the cutting line to help with cutting yield

Glue joint cut length | 8” to 96” | 200~2440mm |

Maximum sawblade diameter | 14” | 355” |

Maximum cutting thickness | 3” | 75mm |

Sawblade bore | 2” | 50.8mm |

Main saw motor | 15 HP | |

Feed motor | 1.5 HP | |

Feed speed (variable) | 36~105 FPM | 11-32 m/min |

Saw arbor brake system | Standard | |

Number of pressure rolls | 8 rolls | |

Distance from saw blade to column | 18.1” | 460mm |

Table dimensions | 69” x 35.4” | 1750x900mm |

Table height from floor | 33.46” | 850mm |

Table width to left of blade | 17.9” | 455mm |

Table width to right of blade | 17.5” | 445mm |

Dust ports | Top: 4”; Bottom: 6” | Top: 100mm; Bottom: 150mm |

CFM Required | 1400 CFM | |

Machine dimensions (LxWxH) | 75”x55”x51” | 1900x1381x1285mm |

Machine weight | 2200 lbs | 1000 kgs |

Shipping dimensions (LxWxH) | 81”x65”x63” | 2060x1640x1580mm |

Shipping weight | 2425 lbs | 1100 kgs |

Electrics | 460/3/60 @ 24 Amps | 230V @ 48 Amps |