Product Description

Large capacity glue line ripsaw with precision straight line results.

The Cantek C14RS Straight Line Ripsaw is a single-blade ripsaw is geared towards the shop looking to increase efficiency in their ripping operations but cannot justify a multi-blade ripsaw. With its precision cast iron chain and track assembly, and extended pressure section, the C14RS can produce a glue joint finish ready for panel glue-up right out of the saw.

Why Cantek C14RS Straight Line Ripsaw?

- Produces a guaranteed glue joint finish to 15′, which eliminates the need to joint the material after ripping

- Precision straight line feeding for parallel and accurate rip cuts

- Eight hold down rollers over six rows ensure material is firmly held during cutting operations for a longer period resulting in a straighter, more precise cut

- Powerful 20HP saw motor for even the most demanding rip applications

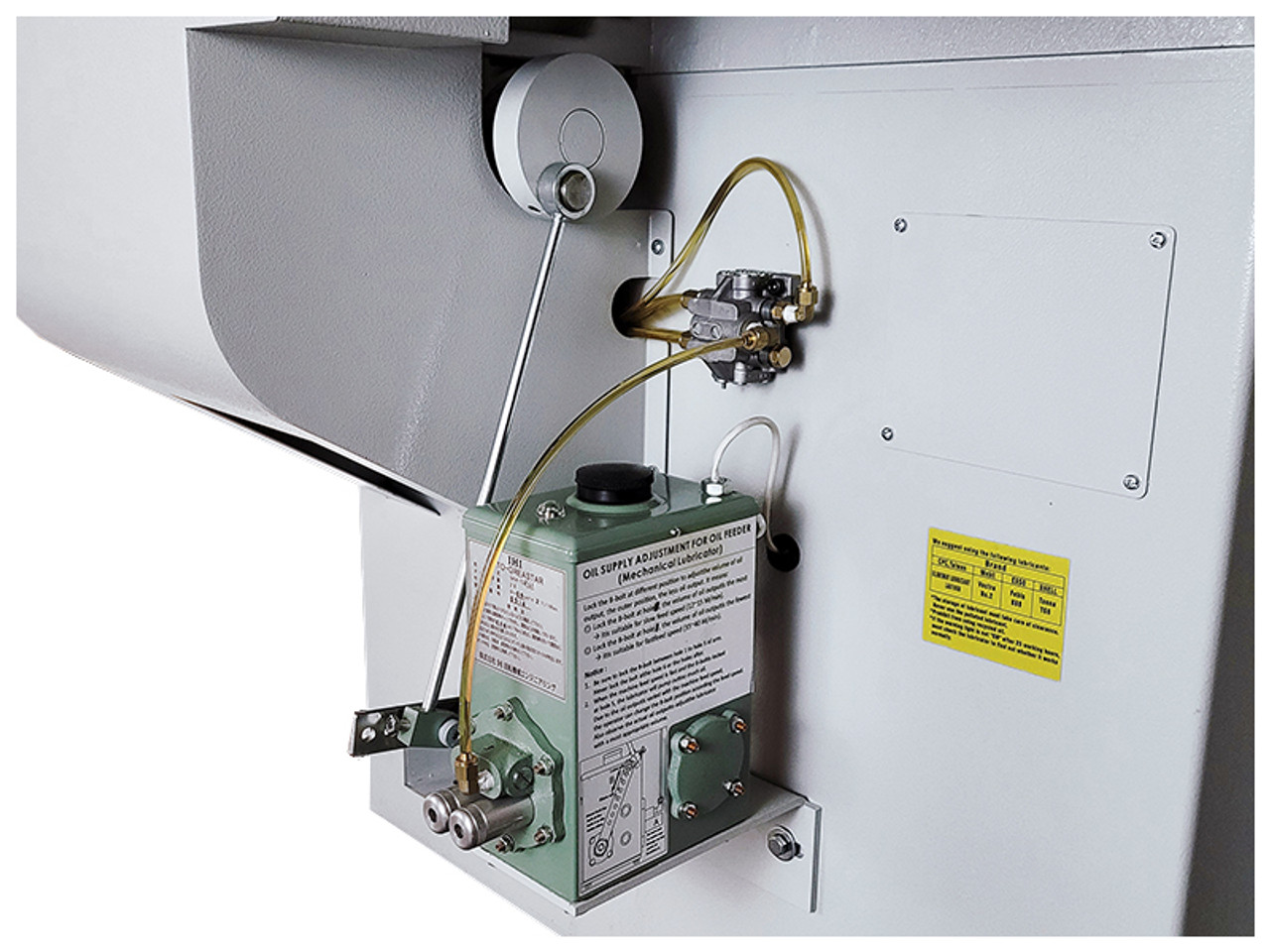

- Maintenance-free chain track with the use of a reliable mechanical lubrication system

- Variable feed speed by frequency inverter for optimum cutting results

- Cast iron saw assembly, column, and table with superior vibration damping properties for optimum cutting results while ensuring long bearing and machine life.

- Very rigid machine body with a welded steel frame

- Absolute straight line feeding with glue joint to 15 ft.

- FC35 cast iron chain track with double-V design ensures precision straight-line ripping with a long wear life

- Precision Built Saw Arbor constructed of nickel-chrome steel, large diameter, accurately ground and dynamically balanced.

- Arbor runs in precision angular contact type ball bearings (eliminates any radial run-out & axial thrust) – V Belt driven from below.

- Mechanical operation chain oiler provides consistent lubrication to the chain track and automatically adjusts to your feed speed.

- When oil runs low, a warning light will come on, and when it gets too low, the machine track stops running to avoid damage to the track.

- Cast iron rip fence is mounted to a large diameter round guide rail with a quick-locking lever for effortless and accurate adjustment.

- 3 sets of anti-kickback fingers: 2 top and 1 set in the table for added operator safety.

- Soft start – Star Delta starter reduces the amp draw on startup.

- Optional laser light to project the cutting line to achieve maximum material yield.

Saw blade diameter | 12″ ~ 15″ | 300 ~ 380mm |

Saw arbor diameter | 1.5″ | |

Saw arbor speed | 3500 RPM | |

Feed speeds variable | 33 ~ 98 FPM | 10 ~ 30 m/min |

Max. cutting thickness: 12″ blade | 3.35″ | 85mm |

Max. cutting thickness: 13″ blade | 3.94″ | 100mm |

Max. cutting thickness: 14″ blade | 4.33″ | 110mm |

Max. cutting thickness: 15″ blade | 4.92″ | 125mm |

Minimum workpiece length | 8″ | 200mm |

Distance between saw and column | 24″ | 609mm |

Arbor motor | 20 HP | |

Feed motor | 2 HP | |

Table size | 50″ x 75″ | 1270 x 1905mm |

Table height | 31.5″ | 800mm |

Dust port size | 5″ | 125mm |

Net weight | 3410 lbs | 1550 kgs |

Machine dimensions | 89″ x 57″ x 57″ | 2269 x 1448x 1449mm |

Shipping weight | 3960 lbs | 1800 kgs |

Shipping dimensions | 83″ x 63″ x 67″ | 2108 x 1600 x 1702mm |

Electrical requirements | 230/3/60 = 60.8 amps460/3/60 = 30.4 amps575/3/60 = 24.1 amps | |