Product Description

Save time and speed up production in your ripping operations.

The CANTEK 303S Straight Line Ripsaw is a straight line ripsaw that is the ideal ripping upgrade for those looking to prepare material for a moulder or for producing face frame material. The 303S automatically feeds the material for consistent rip results. The cast iron feed chain runs on double V guide rails and holds the material firmly for precision straight cutting. A powerful 10 HP motor with maximum 12” blade provides a cutting depth up to 3.35”. A micro adjustable infeed fence allows for quick setups to ensure precise rip widths with fast adjustments.

Why CANTEK 303S Straight Line Ripsaw ?

- Rigid machine body consists of a thick welded steel frame with an integral table which is fitted with a sturdy cast column.

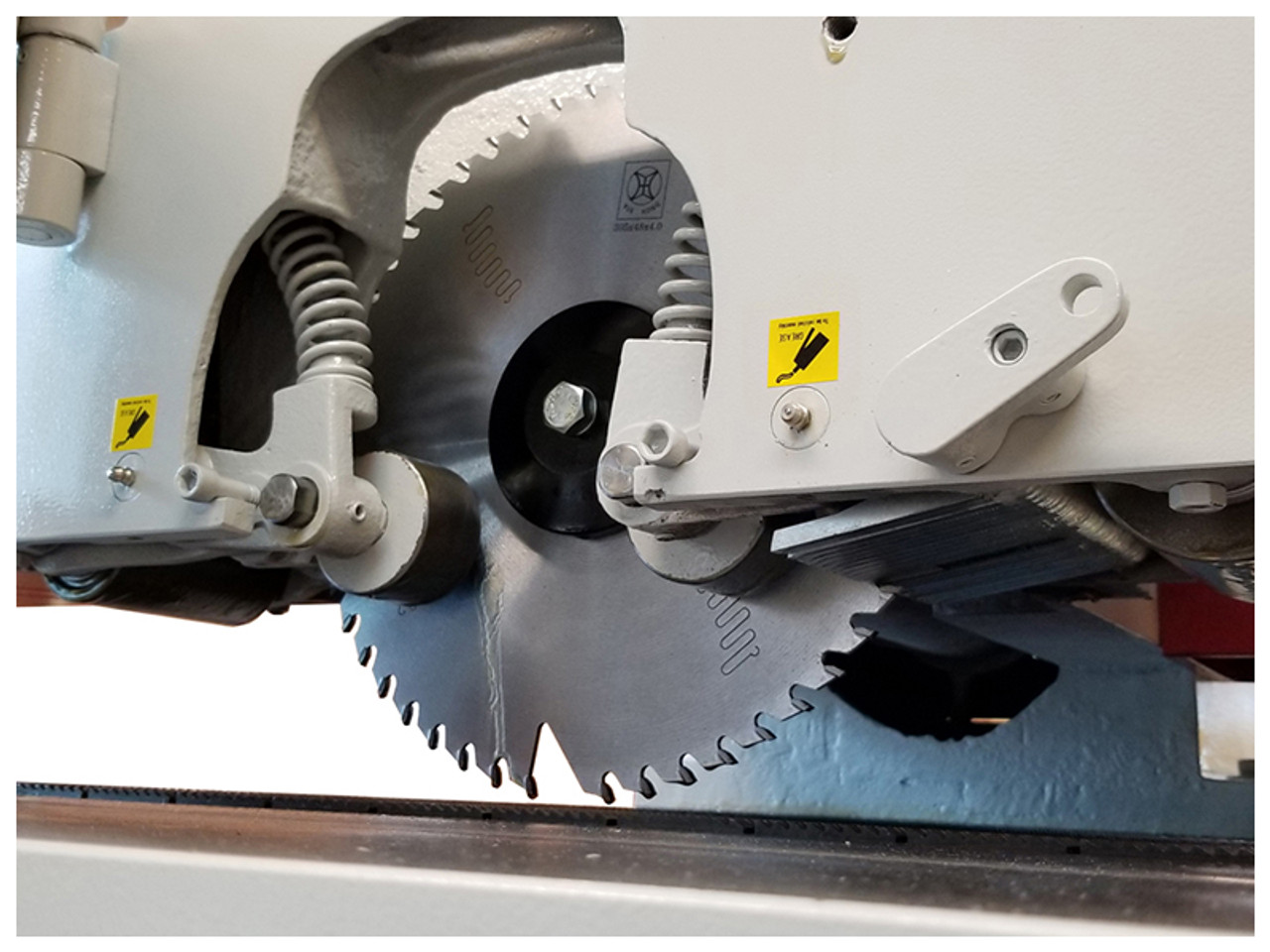

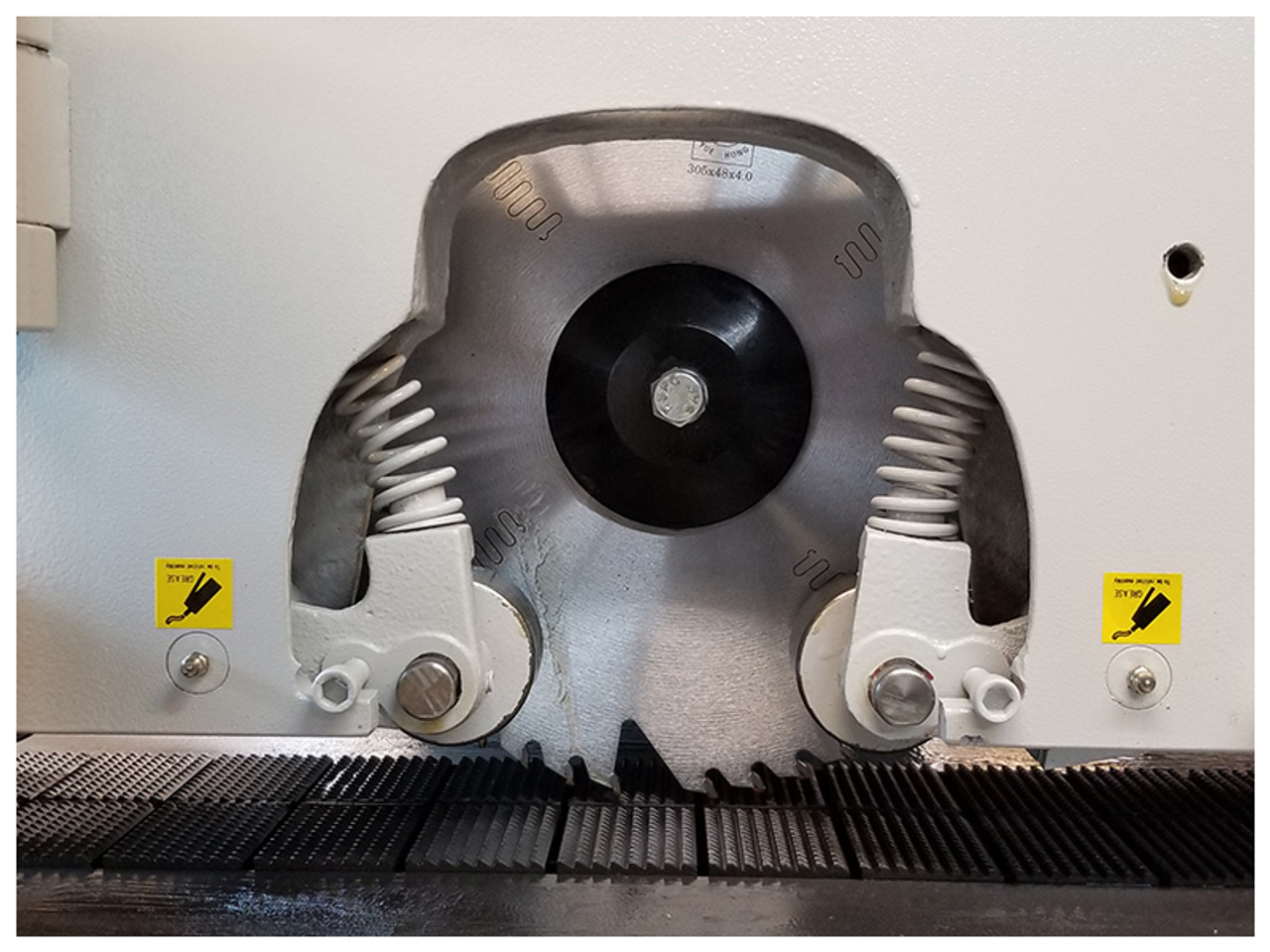

- Precision built saw arbor constructed to ensure precision cutting without vibration.

- Cast iron upper assembly & cast iron table with superior vibration damping for optimum results

- Micro adjustable fence by rack and pinion for fast setups with precise results

- Cast iron chain and track assembly is precision machined and hardened for maximum wear resistance with superior cut quality

- Two rows of anti-kickback fingers for safe operation

- Swing down rear table prevents short workpieces and thin edgings from jamming in the machine

- Electronic chain lubricator provides consistent lubrication to the chain track for optimum wear resistance

- Powerful 10HP motor

- Three feed speeds can be externally adjusted for operator convenience

- Mechanical digital readout for setting the workpiece thickness

- 12” blade is included

- Optional laser light for projecting the cutting line

Saw arbor diameter | 1″ |

Saw blade diameter | 8 – 12″ |

Saw arbor speed | 4500 RPM |

Feed speeds | 3 (50, 65, 85 FPM) |

Maximum workpiece thickness | 3.35″ |

Minimum workpiece length | 8″ |

Pressure rollers | 4 rows (6 rollers) |

Distance between saw and column | 13 ¾” |

Arbor motor | 10 HP |

Feed motor | 1 HP |

Table size | 30″ x 50″ |

Table height | 31-7/8″ |

Net weight | 1870 Lbs |

Shipping weight | 2310 Lbs |

Machine dimensions | 61″ x 38″ x 53″ |

Shipping dimensions | 59″ x 46″ x 59″ |

Electrical requirements | 230/3/60 = 32.2 Full Load Amps |