Product Description

New Technology for Flooring Companies

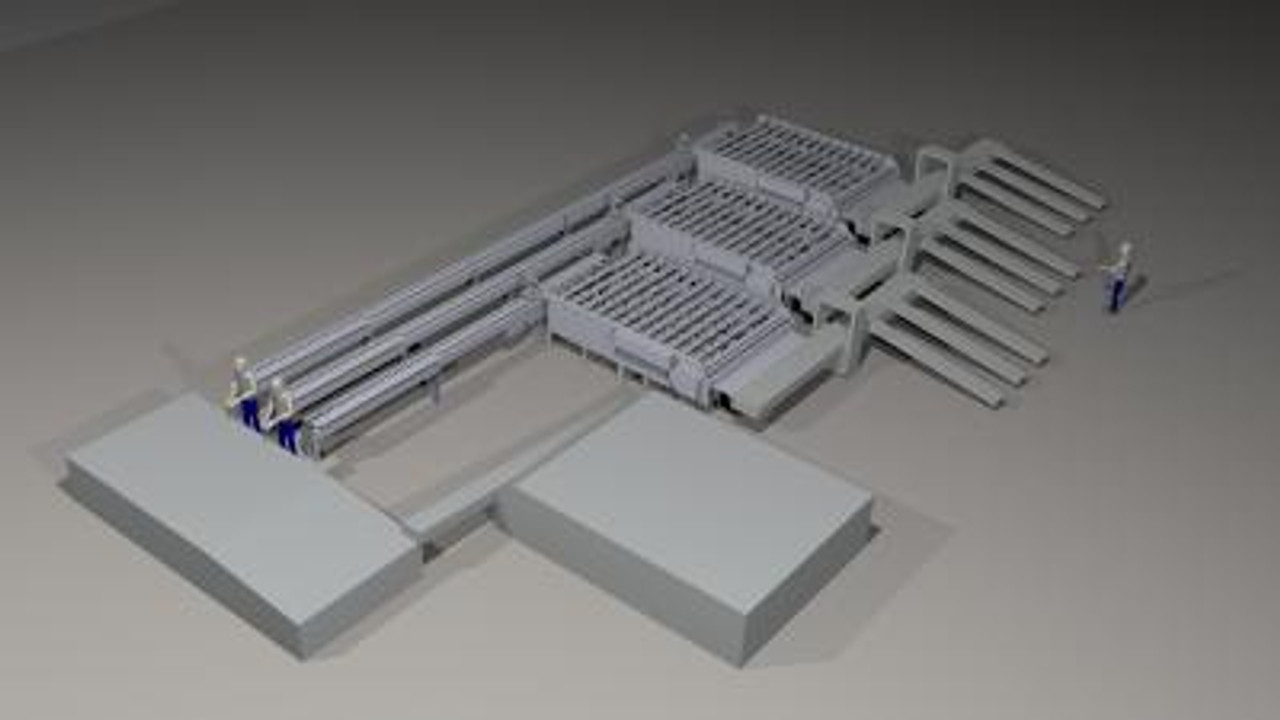

We have taken proven technology from our Opti-Sizer (1986), and our Opti-Match (2005) to develop a machine unlike any other. Random flooring strips are fed in one end and nested bundles are produced at the other end.

In addition to producing bundles of varying length and width, the Cameron software (devoloped, written and supported in-house) tracks incoming and outgoing data. The net result is that you see savings in both labor and material.

- Simple Design

- Easy to Install (1 day or less)

- Easy to Operate

- Easy to Maintain

- Increase Productivity

- Save Labor

- Save Material

How it Works:

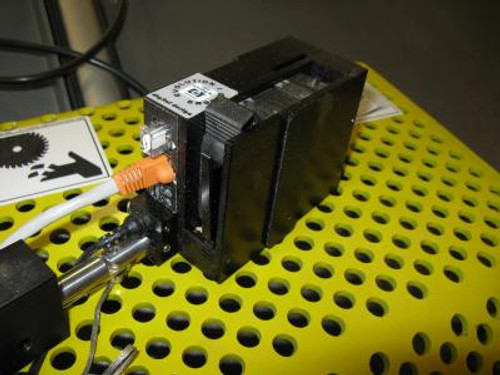

Flooring strips of random length enter the machine where they are measured for length. Strips are released by two sets of stops onto the main conveyor. At precisely the right time, a strip is scooped off of the main conveyor by an innovative lifting system. A computer processes the lengths of the strips to determine which combination of strips will produce an accurate length row. The machine constantly picks up and puts down strips to create rows. Rows are accumulated on the outfeed to create layers on the outfeed table. Layers are stripped off of the outfeed table to create bundles. Completed bundles are pushed off of the outfeed onto a conveyor, ready for strapping and packaging.

Advantages:

- Eliminates Repetitive Manual Labor

- Controls Square Footage in Each Bundle

- Produces More Even Bundles

- Tallies Material Automatically