Product Description

Taylor Manufacturing's Conveyorized Applicator

- (3) Different Widths: 13", 26", 39"

- Consistent and Accurate Application

- No Nightly Clean Up

- Adjustable Doctor Roll

- Safety Clutch

- Removable Glue Roll

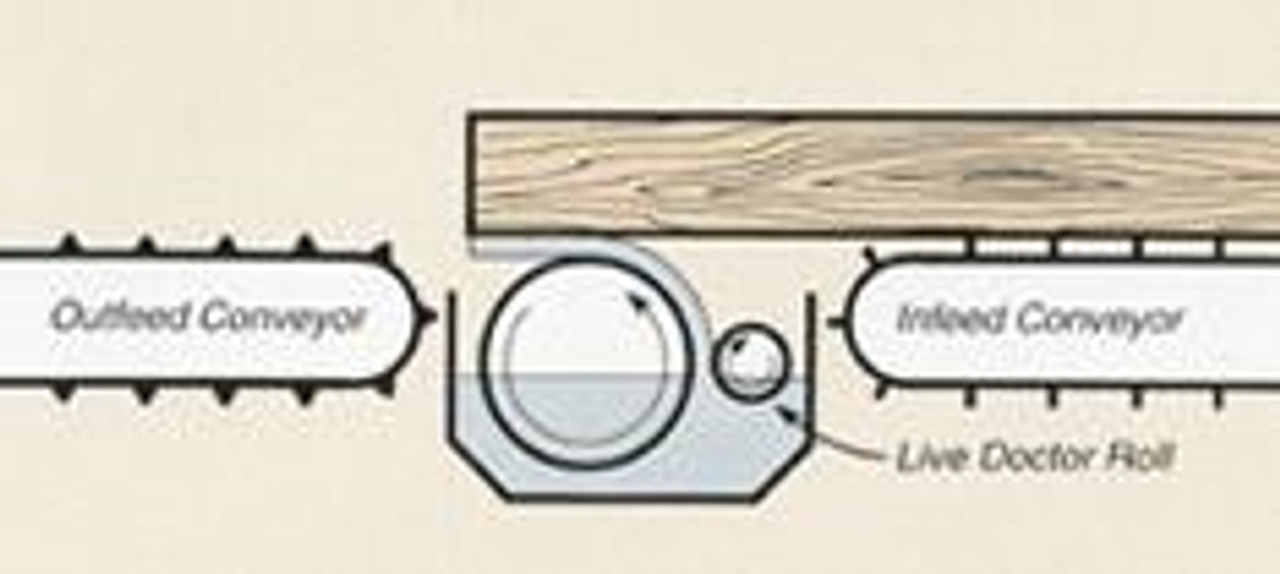

The Taylor Conveyorized Glue Applicator with Return Conveyor is an automated glue application and stock handling system. The system applies adhesive to the wood stock before clamping, and returns glued panels to be stacked.

Applicators come equipped with a large infeed roller, which allows operators to roll stock onto the infeed end. The Glue Applicator conveyer is started and stopped automatically via an electric eye either at its infeed end or at its outfeed end. The glue roll located in the center of the machine applies glue. A live Stainless Steel Doctor Roll insures a complete and even adhesive coating. The Doctor Roll is adjusted by thumbscrews, which regulate glue coat thickness. This reduces waste, clean up time and glue costs.

A safety slip clutch protects the conveyor chain against damage when careless operation results in wood jamming the conveyor. This feature reduces down time and is self-healing so machine returns to normal function once the jammed stock is removed.

EASY CLEAN UP:

Daily: The Conveyorized Glue Applicator is equipped with a stainless steel glue pan cover. Our system seals the glue area and keeps the glue roll moist. Nightly storage of adhesive minimizes clean up time and extends production time 1/2 hour per machine per day.

Weekend: The Taylor system again minimizes clean up. The Applicator features a removable glue roll. The glue pan and roll are easily removed, cleaned and replaced, ready for production the following week.