Product Description

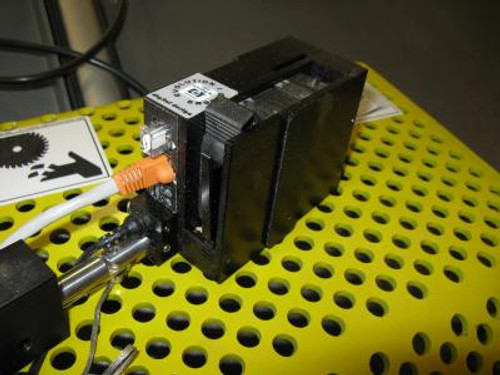

Cameron Automation's The Skew

Cameron Automation has pushed the envelope once again to simplify sophisticated equipment and bring it to the small shop to increase yield and save labor. The Skew is our answer for Rip Optimization in a custom shop. It will quickly transform any small hand-fed gang saw into a full and complete rip optimization system. Cameron has further refined their rip software to make it easy and affordable for the small shop.

Typical Skew users:

- Custom Moulding & Millwork.

- Mid-Size Custom Cabinet Shop.

- Wholesale Lumber Distributor.

- Advantages Over Hand Feeding:

- Increase Safety. 7-10% Increase in yield.

- Extremely accurate positioning of boards. (No yield loss due to misalignment).

- Arbor Optimization.

- Simulations.

- Tallies both incoming and outgoing material automatically.

The Skew can be installed on your existing gang rip saws:

- All Mereen-Johnson rip saws

- Raimann KM310

- Progressive

- Newman Whitney

- Cantek

- Kentwood

Advantages of the Skew:

- Skewing fence increases yield

- Automate any Gang Rip Saw, fixed or movable

- No additional infeed material handling equipment required

- Single operator loads and defects

- Automatic Skewing for even higher yields...get 2-3% additional yield

- Increase safety

- Catalog each and every board

- Machine ships assembled

- Up & Running in 1 day

- Communicates with moving blade saws to position blades automatically.